What Makes Up a Coating?

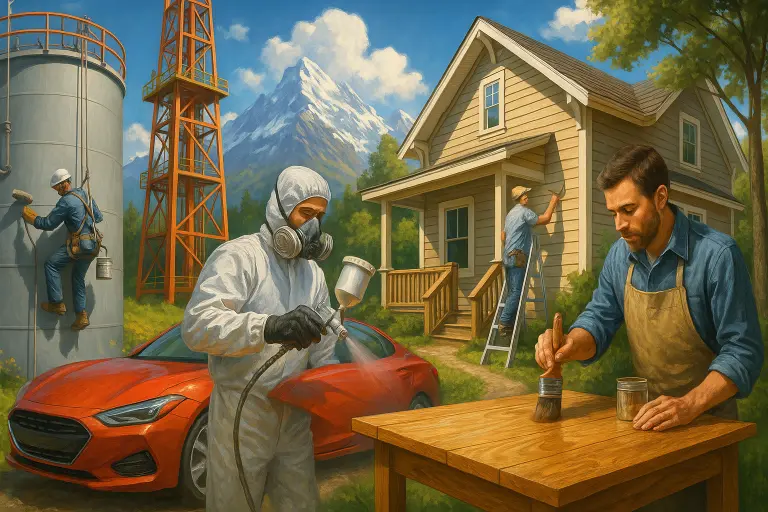

Coatings are an integral part of various industries, providing protective, decorative, or functional finishes on surfaces. Whether it’s the paint on a car, the layer on a piece of machinery, or a protective film on a building, coatings serve many purposes. However, to create these effective coatings, manufacturers use a variety of ingredients—known as additives—that enhance the properties of the coating, making it more durable, flexible, or resistant to specific environmental conditions.

In this simple guide, we will explore what makes up a coating, focusing on the role of additives in the formulation process. By the end of this article, you’ll be equipped with the knowledge to make informed decisions about selecting the right additives for your specific coating needs.

What Is a Coating?

A coating is a layer of material applied to the surface of an object to improve its properties, such as protection against corrosion, environmental factors, and wear. It can also serve a decorative purpose, providing color or texture. Coatings are commonly used in automotive, industrial, architectural, and household applications. The key to an effective coating lies not just in the material itself but also in the additives mixed into it.

1- Resins

Resins are the primary binding agents in coatings. They form the film that adheres to the surface and gives the coating its mechanical properties, such as flexibility, hardness, and durability. Different types of resins—such as epoxy, acrylic, polyester, and polyurethane—are chosen based on the desired properties of the coating.

2- Solvents

Solvents are used to dissolve the resins, pigments, and other components to create a liquid mixture. They help control the viscosity of the coating, making it easier to apply. Once applied, the solvent evaporates, leaving behind the solid film.

3- Pigments

Pigments give coatings their color and opacity. They can also contribute to the coating’s ability to block UV light or prevent corrosion. Pigments are available in organic or inorganic forms, with each offering unique properties depending on the application.

4- Additives

Additives are the ingredients added in small quantities to modify the properties of the coating. While resins, solvents, and pigments provide the fundamental structure and function of the coating, additives fine-tune its performance. They help improve characteristics such as flow, leveling, curing, and protection.

Leveling Agents

…………………………

Rheology Modifiers

Rheology modifiers are used to control the flow and viscosity of the coating. By adjusting the thickness or consistency of the coating, these additives ensure that the coating can be applied smoothly without dripping or running. Rheology modifiers are especially important in industrial applications where precision and even application are required.

Wetting and Dispersing Agents

Wetting agents help reduce the surface tension of the coating material, allowing it to spread more evenly across the surface. Dispersing agents are used to break up pigment particles, ensuring they are evenly distributed throughout the coating. These additives are especially important in coatings that require uniform color and texture.

Rheology Modifiers

Rheology modifiers are used to control the flow and viscosity of the coating. By adjusting the thickness or consistency of the coating, these additives ensure that the coating can be applied smoothly without dripping or running. Rheology modifiers are especially important in industrial applications where precision and even application are required.

Coatings

Coatings Inks

Inks